A research project led FWPA’s National Centre for Timber Durability and Design Life has commenced a testing program for materials used in Hazard Class H3, which covers applications that are outside, above ground and exposed to the weather. The project represents the first time in 30 years that such a range of species, products and preservatives has been tested. Source: Timberbiz

The team wanted to develop information on the durability performance of the tested materials in engineering terms that could be used to enhance the CSIRO Service Life Prediction Models, developed more than 20 years ago by Dr Robert Leicester. The original models used field test data obtained from long-term trials conducted across the country to predict decay occurrence and progress. However, these models were based on a limited data set and did not include many of the treatments currently used for wood in outdoor exposures.

The project aims to create a more accurate understanding of timber properties, which will support structural engineers to appropriately select timber and consequently generate increased usage.

An exceptionally large trial is being established, with support from FWPA, Lesley Francis Research Scientist, Queensland Department of Agriculture and Fisheries at DAF, Chris Fitzgerald, Principal Technician at DAF, Stuart Meldrum, Senior Technician at DAF, Jack Norton Senior Principal Scientist at DAF, and Professor Jeff Morrell, Director of the National Centre for Timber Durability and Design Life.

It will test a range of traditional wood preservatives and more recently developed treatments, as well as modified wood products that have altered wood chemistry. These tests will be conducted on plywood, LVL, oriented strandboard and solid wood. Heartwood of spotted gum and merbau (kwila) along with a wood-plastic composite will also be included in the trial.

The tests will collect durability performance data on new treatments and wood-based composites, by using traditional visual assessments as well as tests to assess changes in engineering properties over time.

The research team gratefully acknowledges industry support through the provision of test materials, treatments and expertise.

The trial includes more than 8000 test pieces that will be exposed at DAF Far North Queensland test site, as well as a recently established field test site located at the DAF Maroochy Research Facility, near Nambour. The trial will start yielding data for untreated controls over the next two to five years, while results for treated samples will take longer to develop.

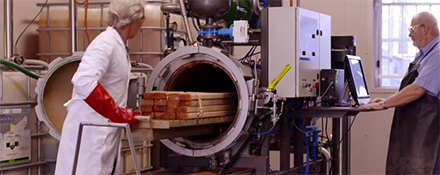

The majority of staff at DAF’s Salisbury Research Facility have contributed to this project – from cutting, weighing and sorting timber, to treating and acoustically testing each beam that will be used to assess flexural property changes over time.

The tests will include ground proximity tests where blocks are placed directly on concrete above ground, as listed in the Australasian Wood Preservation Committee protocols. Also included will be an above-ground sandwich test used in the U.S, where blocks are strapped together to create timber sandwiches that are exposed on racks above ground. In addition, the team will conduct tests involving beams being placed on timber supports on concrete above the ground, to assess changes in flexural properties.

This data will feed into the CSIRO’s predictive service life models. While the existing CSIRO models were revolutionary for their time and Dr. Leicester received the Wallenberg Prize (the Nobel Prize for Forestry), there is a critical need for better data to help improve the models and make them more relevant for engineering applications.