Hybrid construction offers construction companies a more sustainable way of building without changing their current building methods. Metsä Wood and its partners have designed a hybrid sandwich wall element, which will renew offsite construction. Source: Timberbiz

The innovation combines concrete with Kerto LVL (laminated veneer lumber). The lighter weight of the hybrid sandwich wall elements proved to be a valuable benefit in the first construction project at Metsä Fibre’s Rauma sawmill.

The production of the new hybrid sandwich wall elements, which are used in the sawmill’s log sorting building, went as planned at the precast element manufacturer Lipa-Betoni’s factory. This is the first time the factory produced hybrid wall elements.

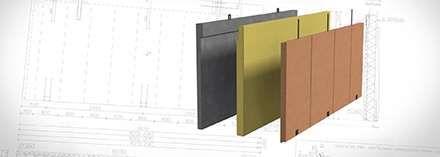

In the production of a hybrid sandwich wall element, a Kerto LVL panel forms the load-bearing core. This is followed by an insulation layer and reinforced concrete facade.

“After overcoming the initial challenges, the production of the hybrid sandwich wall elements has been as easy as the production of concrete sandwich elements. We have succeeded in this thanks to the close cooperation with and extensive know-how of our partners,” said Satu Lipsanen, CEO of Lipa-Betoni.

The installation of the hybrid sandwich wall elements for the first floor, 100 m , of the building took five hours.

“The assembly of the hybrid sandwich wall elements has been similar to the usual concrete sandwich elements. We were able to use a lighter crane in the assembly as the hybrid sandwich wall elements are lighter than traditional sandwich elements. Their lighter weight can bring savings in a large construction project,” said Petri Puputti, Construction Manager, Skanska.

Both kinds of elements have identical connections in the bottom, and the seams of the hybrid sandwich elements have timber screws. He also highlighted that after the assembly of hybrid sandwich wall elements, the seams are finished and there is no need to do seaming, concrete grinding or cleaning, as is the case with concrete sandwich panels.

The sorting building will be ready by the end of 2021. The sawmill is planned to be ready in Q3 2022.