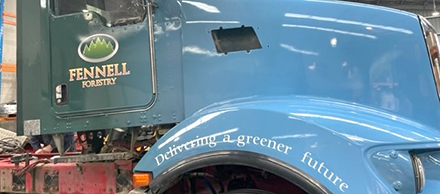

Fennell Forestry in Mount Gambier has electrified a former diesel engine B-double in a bid to make its freight movements greener.

Fennell is set to take over the first electric B-double loggers this month with a purpose-built charging station under construction in its yard. Janus Electric, a start-up in New South Wales, has developed technology that allows companies to convert existing diesel engine trucks into electric powered vehicles, with zero emissions. Source: tornadopix.com

General Manager Lex Forsyth said the team developed a modular conversion system that allows it to convert most major engines, trucks and OEM products.

Lex Forsyth is CEO of New South Wales start-up Janus Electric, which is converting existing diesel trucks into zero-emission electric vehicles.

“There are currently about 105,000 registered Class 8 trucks in Australia,” he said.

“Our solution is a perfect fit for about 80% of the market here in Australia.”

Mr. Forsyth said the significant capital investment required to purchase a new truck versus converting an existing vehicle was a key factor in the design of the Janus units.

“We used the conversion model because the truth is we only produce 5,000 new trucks a year for our market,” he said.

“If we were to try to change the way we consume energy and go for a greener transportation and logistics mission, it would take 20 years if we started producing new trucks today.

“The important thing for fleet operators is that after five years, the trucks are due to be rebuilt anyway.

Instead of rebuilding the diesel engine, [they can put] in a new electric motor and away from diesel and maintenance costs of running a diesel vehicle.

Unlike electric vehicles that plug into a charging station, Janus’ electrical system replaces a truck’s batteries like a racing car that replaces its tyres while it’s idling.

“We have created interchangeable battery technology to mitigate the problem of vehicles parking for freight and the loss of advantage for fleet operators,” Forsyth said.

“There are two batteries on the truck … they go to where the fuel tanks were on the car, and they are replaced.

“We are currently doing this with a 3-ton forklift and swapping the two batteries takes about four minutes.”

But going forward, Forsyth envisions a more automated approach.

“As we get to a larger scale, the trucks will pass through an automated charging changing station where you will simply drive the truck below the charging station and the batteries are stacked on top of it,” he said.

“It’s no different than putting a 2-ton pallet on a truck, it’s just automated.”

The Janus battery stacking station can also double as an energy storage system, charging the batteries during periods when the power grid is producing excess power.

“The beauty of our interchangeable technology is that we don’t rely on the grid to get that energy back because it always goes to the logging trucks,” Forsyth said.

“It provides significant savings to fleet operators [by] Reduce fuel and maintenance costs but the environment is the main benefit from it.”

Nathan Payne, chief executive of the South Australian Forest Products Association, said the industry’s transition to electric vehicles would take time but was inevitable.

“There is definitely a global drive for decarbonisation…and I think that will mean we’ll see technologies like electric trucks, and possibly hydrogen trucks, entering the fleet,” he said.

“We are a very green industry, but that doesn’t mean we can’t do a better job, which is why, across the industry, we’re looking at ways we can remove carbon from our operations.

“I am absolutely convinced that in the next five to 10 years, electric trucks will become a much more important part of managing this country’s shipping efforts.”